Food Technologists has published this State of Science Summary to update readers on the environmental impacts of food packaging, packaging materials, and packaging varieties .

Advances in food processing and food packaging play a primary role in keeping the food supply in Turkey among the safest in the world. Simply put, packaging preserves the benefits of food processing once the process is complete, allowing food to travel safely over long distances from their point of origin and still be healthy at the time of consumption. However, packaging technology must balance food preservation with other issues such as energy and material costs, increased social and environmental awareness, and strict regulations regarding pollutants and municipal solid waste disposal.

Roles of Food Packaging and Materials

The main tasks of food packaging are to protect food products from external influences and damage, to contain food, and to provide content and nutritional information to consumers. Traceability, convenience and tamper indication are secondary functions of increasing importance. The goal of food packaging is to contain food in a cost-effective way that meets industry requirements and consumer demands, maintains food safety and minimizes environmental impact. Here is what you need to know about food packaging, packaging materials and packaging types.

Protection / containment

food packaging can delay product spoilage, preserve the beneficial effects of processing, extend shelf life, and preserve or improve the quality and safety of food. In doing so, the packaging provides protection against 3 main classes of external factors: chemical, biological and physical.

chemical protection minimizes compositional changes triggered by environmental influences such as exposure to gases (typical oxygen), moisture (gain or loss), or light (visible, infrared or ultraviolet). Many different packaging materials can provide a chemical barrier. Glass and metals provide an almost absolute barrier to chemical and other environmental influences, but few packages are all glass or metal, as closure devices are added to facilitate both filling and emptying. Closing devices may contain materials that allow minimal permeability. For example, plastic closures have some permeability to gases and vapors, as do gasket materials used in closures to facilitate closure and metal can closures to seal after filling.

Biological protection provides a barrier against microorganisms (pathogens and degradants), insects, rodents and other animals, thus preventing disease and spoilage. In addition, biological barriers provide the conditions for controlling aging (maturation and aging). Such barriers function through multiple mechanisms, including blocking access to the product, inhibiting odor transfer, and protecting the interior environment of the package.

Physical protection protects food from mechanical damage and includes buffering against shock and vibration encountered during delivery. Typically developed from cardboard and corrugated materials, physical barriers are resistant to impacts, abrasions and crushing, so they are widely used as shipping containers and packaging for sensitive foods such as eggs and fresh fruit. Proper physical packaging also protects consumers from various hazards. For example, childproof covers prevent access to potentially dangerous products. Additionally, substituting plastic packaging for products ranging from shampoo to soda bottles has reduced the danger from broken glass containers.

Marketing and information

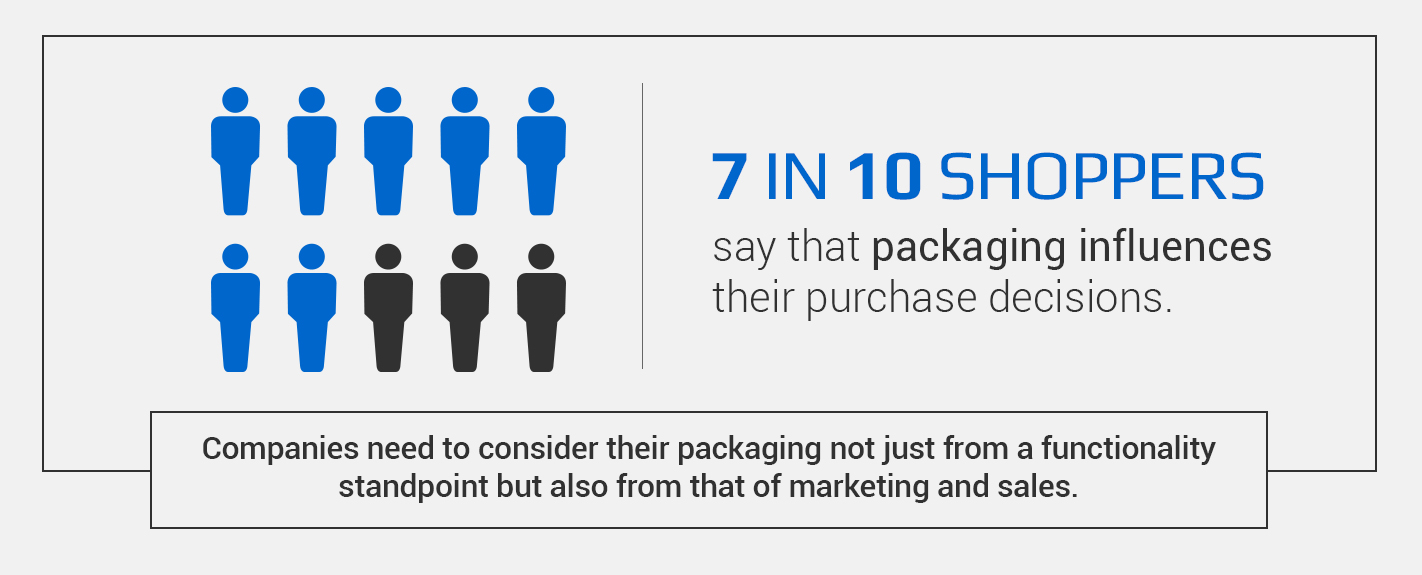

A package is the face of a product and often the only product expression that consumers experience before purchasing. As a result, different or innovative packaging can increase sales in a competitive environment. The package can be designed to enhance product image and/or differentiate the product from its competitors. For example, larger labels can be used to place recipes. Packaging also provides information to the consumer. For example, the packaging label; meets legal requirements for product identification, nutritional value, ingredient declaration, net weight and manufacturer information. In addition, the package conveys important product-related information such as cooking instructions, brand identification, and pricing. All these improvements can affect waste disposal.

Traceability

Traceability is defined as “the ability to track the movement of a food at certain stages/stages of production, processing and distribution”. Traceability has 3 purposes: to improve supply management, to facilitate tracking for food safety and quality purposes, and to differentiate and market foods with subtle or undetectable quality characteristics. Food manufacturing companies add unique codes to the packaging labels of their products; this allows them to track their product throughout the distribution process. Codes are available in a variety of formats (for example, printed barcodes or electronic radio frequency identification [RFID]) and can be read manually and/or by machine.

Ease

Convenience features such as ease of access, use and disposal; product visibility; reliability; and microwave availability greatly influence package innovation. As a result, packaging plays a vital role in minimizing the effort required to prepare and serve food. Oven-safe trays, simmer bags, and microwaveable packaging allow consumers to cook an entire meal with virtually no preparation. New closure designs provide ease of opening, reliability and special dispensing features. For example, a cookie manufacturer recently introduced a flexible bag with a scored section that provides access to cookies. A removable seal membrane seals the opening before the sale and allows for reclosing after opening. In food packaging and packaging, types Advances have facilitated the development of modern retail formats that offer consumers the convenience of one-stop shopping and the availability of food from anywhere in the world. These convenience features add value and competitive advantage to products, but can also affect the amount and type of packaging waste that needs to be disposed of.

Tampering indicator

It has resulted in special packaging features designed to reduce or eliminate the risk of deliberate tampering, tampering and adulteration in food and pharmaceutical products. Although any package can be opened, the anti-tamper features cannot be easily changed. Tamper evident features include banding, custom membranes, detachable caps, and custom printing on bottle liners or compound boxes, such as graphics or text that change irreversibly when opened. The special edition also includes holograms that cannot be easily copied. Tamper-evident packaging often requires additional packaging materials, which makes disposal problems worse, but the benefits often outweigh any disadvantages.

Materials Used in Food Packaging

Packaging design and construction play an important role in determining the shelf life of a food product. Choosing the right packaging material and technology preserves product quality and freshness during distribution and storage. Materials traditionally used in food packaging include glass, metals (aluminum, foils and laminates, tin and tin-free steel), paper and cardboard, and plastics. Moreover, a wide variety of plastics have been introduced in both rigid and flexible forms. Today's food packages often combine several materials to take advantage of the functional or aesthetic properties of each material.of food packaging developments in the field may affect the environmental impact of packaging, while research into improvement continues.

Glass

Glass has an extremely long history in food packaging; The first glass objects used to hold food are believed to have appeared around 3000 BC. The manufacture of glass containers involves heating a mixture of silica (glass former), sodium carbonate (melting agent), and limestone/calcium carbonate and alumina (stabilizers) to high temperatures until the materials melt into a thick liquid mass that is poured into molds. Recycled broken glass (broken glass) is also used in glass production and can make up 60% of all raw materials. Glass containers used in food packaging are often surface coated to provide lubrication in the production line and to eliminate scratching or surface wear and line jams. Glass coatings also increase and protect the strength of the bottle to reduce breakage. Improved fracture resistance

Metal

Metal is the most versatile of all packaging forms. It combines excellent physical protection and barrier properties, formability and decorative potential, recyclability and consumer acceptance. The 2 most commonly used metals in packaging are aluminum and steel.

Aluminum Commonly used to make cans, foils, and laminated paper or plastic packaging, aluminum is a light, silvery-white metal derived from bauxite ore, where it exists with oxygen as alumina. Magnesium and manganese are often added to aluminum to improve its strength properties. Unlike most metals, aluminum is highly resistant to most types of corrosion; The natural aluminum oxide coating provides a highly effective barrier against the effects of air, temperature, humidity and chemical attack.

Aluminum foil is made by rolling pure aluminum metal into very thin sheets and then annealing to achieve dead-fold properties (a ply or ply made on the film will remain in place) that allow it to be rigidly folded. Also, aluminum foil is available in a wide variety of thicknesses, with thinner foils for wrapping food and thicker foils used for trays. Like all aluminum packaging, the foil provides an excellent barrier against moisture, air, odors, light and microorganisms. It is inert to acidic foods and does not require polish or other protection. Although aluminum is easily recyclable, foils cannot be made from recycled aluminum without pinholes in thin sheets.

Laminates and metalized film lamination of packaging involve bonding aluminum foil to paper or plastic film to improve barrier properties. Thin dimensions facilitate application. Although lamination to plastic provides heat sealability, the gasket does not completely block moisture and air. Because laminated aluminum is relatively expensive, it is typically used to package high-value foods such as dried soups, herbs, and spices. A cheaper alternative to laminated packaging is metalized film. Metalized films are plastics containing a thin layer of aluminum metal. These films have improved barrier properties against moisture, oils, air and odors, and the highly reflective surface of aluminum is attractive to consumers. More flexible than laminated films, metalized films are often used to pack snacks.

Tin The tin produced from low carbon steel (ie black plate) is obtained by coating both sides of the black plate with thin layers of tin. The coating is obtained by immersing steel sheets in the molten tin (hot dipped tin) or by electro-depositing tin on a steel sheet (electrolytic tin). Although tin provides some corrosion resistance to steel, tin containers are often lacquered to provide an inert barrier between the metal and the food product. Commonly used varnishes are materials from the epoxy phenolic and oleoresin groups, and vinyl resins.

Plastics

Plastics are made by condensation polymerization (polycondensation) or addition polymerization (multi-addition) of monomer units. In polycondensation, the polymer chain grows by condensation reactions between molecules, accompanied by the formation of low molecular weight byproducts such as water and methanol. Polycondensation includes monomers with at least 2 functional groups such as alcohol, amine or carboxylic groups. In multiple additions, polymer chains grow by addition reactions where 2 or more molecules combine to form a larger molecule without the by-products being released. Polyaddition contains unsaturated monomers; Double or triple bonds are broken to connect monomer chains. In plastic for food packaging, there are many advantages to using Flowable and moldable plastics can be formed into sheets, shapes and structures, offering significant design flexibility. Because they are chemically resistant, plastics are inexpensive and lightweight and have a wide range of physical and optical properties. In fact, many plastics are heat sealable, easy to print, and can be integrated into production processes where the packaging is formed, filled and sealed on the same production line. The major disadvantage of plastics is their variable permeability to light, gases, vapors and low molecular weight molecules.

Polyolefins Polyolefin is a collective term for polyethylene and polypropylene, the 2 most commonly used plastics in food packaging and other less popular olefin polymers. Polyethylene and polypropylene both have a successful combination of properties, including flexibility, strength, lightness, stability, moisture and chemical resistance, and easy workability, and are well suited for recycling and reuse.

Polyesters Polyethylene terephthalate (PET or PETE), polycarbonate and polyethylene naphthalate (PEN) are condensation polymers composed of ester monomers resulting from the reaction between carboxylic acid and alcohol. The most widely used polyester in food packaging is PETE.

Polycarbonate. Polycarbonate is formed by the polymerization of sodium salt of bisphenol acid with carbonyl dichloride (phosgene). It is clear, heat resistant and durable, and is mainly used as a glass substitute in items such as large returnable/refillable water bottles and sterilizable baby bottles.

Polyethylene naphthalate PEN is a condensation polymer of dimethyl naphthalene dicarboxylate and ethylene glycol. It is a relatively new member of the polyester family with excellent performance due to its high glass transition temperature. PEN's barrier properties for carbon dioxide, oxygen and water vapor are superior to those of PETE, and PEN performs better at higher temperatures, allowing for hot refilling, rewashing and reuse.

Polyvinyl chloride (PVC), an addition polymer of vinyl chloride, is a heavy, tough, ductile and medium strength, amorphous, transparent material. It has excellent resistance to chemicals (acids and bases), grease and oil; good flow characteristics; and stable electrical properties. Although PVC is primarily used in medical and other non-food applications, food uses include bottles and packaging films. Because it can be easily thermoformed, PVC sheets are widely used in blister packagings such as meat products and unit dose pharmaceutical packaging.

Polyvinylidene chloride (PVdC) is an additive polymer of vinylidene chloride. It can be heat sealed and acts as an excellent barrier against water vapor, gases and greasy and oily products. It is used in flexible packaging as a monolayer film, a coating or as part of a co-extruded product. Major applications include packaging of poultry, cured meats, cheese, snack foods, tea, coffee and confectionery. It is also used in hot filling, autoclaving, low-temperature storage and modified atmosphere packaging. PVC contains twice as much chlorine as PVC and therefore poses problems with combustion.

Polyamide Polyamides, commonly known as nylon (a brand name for a number of products manufactured by DuPont), were originally used in textiles. Polyamides formed by the condensation reaction between diamine and diacid are polymers in which repeating units are held together by amide bonds. Different types of polyamides are characterized by a number related to the number of carbons in the source monomer. For example, nylon-6 has 6 carbons and is typically used in packaging. It has similar mechanical and thermal properties to PETE, so it has similar usefulness as boiling bag packaging. Nylon also offers good chemical resistance, toughness and low gas permeability.

Paper and cardboard

The use of paper and cardboard for food packaging dates back to the 17th century, with rapid use in the late 19th century (Kirwan 2003). Paper and cardboard are sheet materials made from an interwoven web of cellulose fibers obtained from wood using sulfates and sulfites. The fibers are then pulped and/or bleached and treated with chemicals such as fine killers and reinforcing agents to produce the paper product. The FDA regulates additives used in paper and cardboard food packaging (21 CFR Part 176). Paper and cardboard are commonly used in corrugated boxes, milk cartons, folding cartons, bags and sacks, and wrapping paper. Tissue paper, paper plates and cups are other examples of paper and cardboard products.

Paper Plain paper is not used to preserve food for a long time, as it has poor barrier properties and cannot be heat-sealed. When used as primary packaging (i.e. in contact with food), paper is almost always treated, coated, laminated or impregnated with materials such as wax, resin or lacquers to enhance functional and protective properties. Many different types of paper used in food packaging are as follows:

- Kraft paper — Made by the sulfate treatment process, kraft paper is available in a variety of forms: natural brown, unbleached, heavy-duty and bleached white. Natural kraft is the strongest of all papers and is often used for bags and packaging. It is also used to pack flour, sugar and dried fruits and vegetables.

- Sulfite paper — Lighter and weaker than kraft paper, sulfide paper is glazed to improve its appearance and increase its wet strength and oil resistance. It can be coated for higher print quality and is also used in laminates with plastic or foil. It is used to make small sachets or wraps for packing biscuits and confectionery.

- Greaseproof paper - Greaseproof paper is made by a process known as beating, in which the cellulose fibers undergo a longer-than-normal hydration time that causes the fibers to break down and become gelatinous. These fine fibers are then densely packed to provide a surface that is resistant to oils but not to wet substances. Greaseproof paper is used to wrap snack foods, cookies, candy bars, and other fatty foods, a use that has been replaced by plastic films.

- Glassine - Glassine is wax paper that takes extreme (more hydration) to produce a very dense sheet with an extremely smooth and glossy surface. It is used as a primer for biscuits, cooking oils, fast foods and baked goods.

- Parchment paper — Parchment paper is made from the acid-treated pulp (run through a sulfuric acid bath). The acid modifies the cellulose, making it smoother and impermeable to water and oil, giving it some wet strength. It does not provide a good barrier to air and moisture, is not heat sealable, and is used to package oils such as butter and lard.

PAPER LAMINATES

Paper laminates are coated or uncoated papers based on kraft and sulfide pulp. They can be laminated with plastic or aluminum to improve various properties. For example, paper can be laminated with polyethylene to make it heat sealable and improve its gas and moisture barrier properties. However, lamination significantly increases the paper cost. Laminated paper is used to package dried products such as soups, herbs and spices.

Conclusion

The primary purpose of food packaging and packaging should continue to be to protect the safety, integrity and quality of food. The environmental impact of packaging waste can be minimized by choosing materials prudently, following EPA guidelines, and reviewing packaging expectations for environmental impact. Knowledgeable efforts by industry, government and consumers will foster continuous improvement, and understanding the functional characteristics of packaging will prevent many of the well-meaning but ill-advised solutions that fail to adequately account for both pre-consumption and post-consumer packaging factors.

A wide variety of products about food packaging and sachets on our site you can find to our product catalog suggest you take a look. If you need help, one of our experts will help you. You can contact us at this number +905455571406.

13 Comment(s)

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Leave a Comment